Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

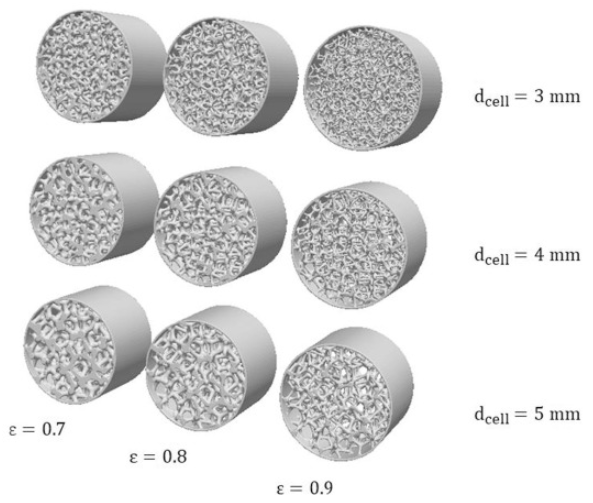

Open-cell foams as structured catalyst supports are promising candidates for the design of high throughput catalytic processes. In this contribution, we employ a coupled numerical and experimental approach to assess the pressure losses in foams. (…) we explore virtually-generated foam models and their 3D printed replicas for a combined CFD and experimental study of fluid dynamics in foams. In particular, we focus our analysis on the low Reynolds number regime, where deviations between the existing correlation and experimental data are more pronounced. We find a very good agreement between CFD simulations and experimental measurements in evaluating the pressure drop of gas flows across foams. The effect of porosity, cell sizes and strut shape are studied, leading to the derivation of an engineering correlation for the pressure drop in open-cell foams. Subsequently, the derived correlation is used to evaluate the trade-off between the external transport rate and the pressure drop, which is a pivotal aspect in most environmental catalytic processes: results show that open-cell foams can outperform honeycomb monoliths in the range of low Reynolds numbers.

A set of raw 3D images has been postprocessed using Avizo 9.4 software to generate a tri-dimensional structure of the scanned sample. In doing so, each voxel is assigned to the fluid or solid phase by selecting a threshold grey value. Once each voxel is assigned, it is possible to extract the 3D reconstruction of the structure.

For Research Use Only. Not for use in diagnostic procedures.