Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

Metal additive manufacturing techniques such as the powder-bed systems are developing as a novel method for producing complex components.

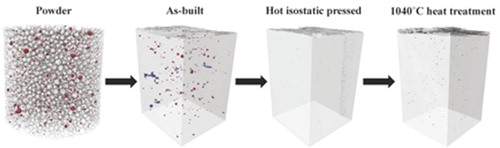

This study uses synchrotron-based X-ray microtomography to investigate porosity in electron beam melted Ti-6Al-4V in the as-built and post-processed state for two different powders. The presence of gas porosity in the starting powder was shown to correlate to porosity in the as-built components. This porosity was observed to shrink after a hot isostatic press treatment, but grow following a subsequent heat treatment. Crystal plasticity simulations were used to observe the effects of various observed pore sizes on mechanical behavior under loading.

Avizo version 9 was used for segmentation and analysis. A minimum of eight face-connected voxels were used as the minimum feature size, establishing a minimum feature size of approximately 1.5 µm.

For Research Use Only. Not for use in diagnostic procedures.