Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

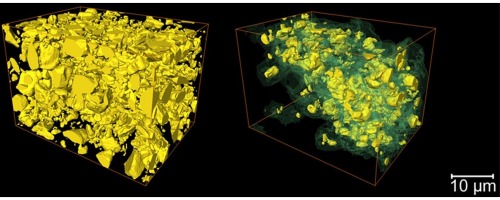

The microstructural degradation of a composite silicon electrode at different stages in its cycle life was investigated in 3D using X-ray nano-computed tomography. A reconstructed volume of 36 μm × 27 μm × 26 μm from the composite electrode was imaged in its pristine state and after 1, 10 and 100 cycles. Particle fracturing and phase transformation was observed within the electrode with increased cycling. In addition, a distinct, lower X-ray attenuating phase was clearly resolved, which can be associated with surface film formation resulting from electrolyte breakdown and with silicon particle phase transformation. Changes in quantified microstructural properties such as phase volume fraction and particle specific surface area were tracked. Electrode performance loss is associated with loss of active silicon. These imaging results further highlight the capability of high resolution X-ray tomography to investigate the role of electrode microstructure in battery degradation and failure.

For Research Use Only. Not for use in diagnostic procedures.