Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

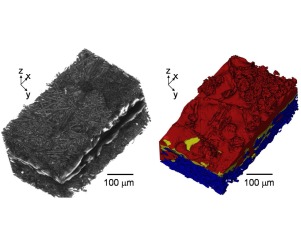

The hot pressing process for fabricating membrane electrode assemblies (MEAs) has been widely adopted, yet little is known of its effects on the microstructural properties of the different components of the MEA. In particular, the interaction of the electrolyte, electrode and gas diffusion layer (GDL) due to lamination is difficult to probe as conventional imaging techniques cannot access the internal structure of the MEA. Here, a novel approach is used, which combines characterisation of hot-pressed membrane electrode assemblies using X-ray computed tomography, thermogravimetric analysis, differential scanning calorimetry and atomic force microscopy, with electrochemical performance measurements from polarisation curves and high-frequency impedance spectroscopy.

For Research Use Only. Not for use in diagnostic procedures.