Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

The research focuses on the fiber behavior following injection molding on a spiral-flow mold, particularly its fiber orientation behavior. The behavior of the glass fiber will be examined by altering key experiment settings, the screw speed and the back pressure, and employing different melt paths. The results show that the application of high back pressure and high screw speed decreased the fiber length but successfully increased the fiber orientation average to the flow direction. The design of the melt flow paths that employed here are showing imbalance mold filling phenomena that resulting asymmetric fiber orientation hierarchy. Meanwhile, with the combination of correct settings in the experimental parameters and the right choice of melt flow path can create a very high tensor value with more than 80% fibers aligned to the flow direction.

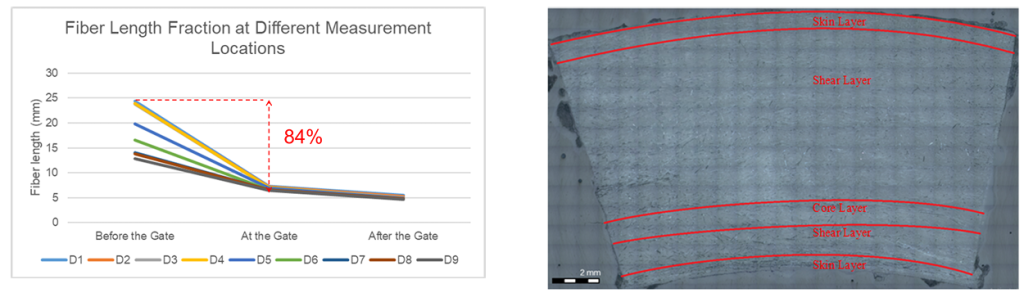

Extreme degradation on D samples when entering the gate. Fiber orientation layers hierarchy from micro-CT scan and OM.

The image analysis was conducted to analyze and separate the fibers with its matrix. Both OM results and micro-CT scan results were observed using Avizo 3D Software. An image intensity approach is used to analyze the images with the goal of automatically calculating the fiber orientation tensor and detecting the fiber length. The intensity difference between the pixels indicates these two stages in the image because glass fiber absorbs more X-rays than polypropylene.

For Research Use Only. Not for use in diagnostic procedures.