Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

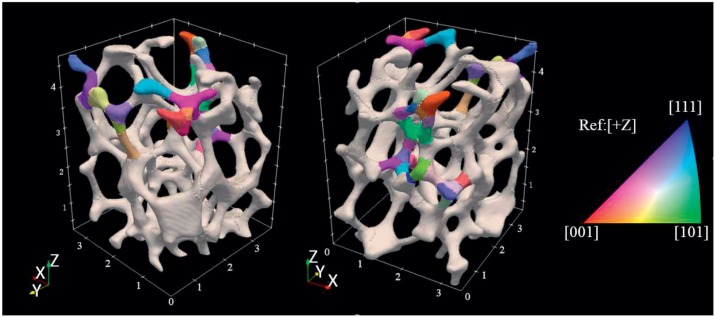

The complex mechanical response of open-cell foams depends strongly on the hierarchy of length scales inherent in them, from engineering-part scale to the ligament scale through the grain scale down to the crystal-lattice scale. A first step toward understanding and predicting the coordinated mechanical response across length scales requires characterizing the open-cell foam structure in three dimensions at relevant scales. Here, we present an initial attempt to digitally represent a physically-realized aluminum alloy foam in terms of both its geometry/topology as well as its underlying crystallographic orientations by integrating several advanced techniques. Specifically, we use a combination of X-ray computed tomography and X-ray diffraction microscopy in conjunction with synthetic grain mapping. Experimental investigation of the foam shows relatively large grain sizes with respect to the ligament length scale, implying that competing mechanics at different length scales (i.e. grain scale vs. ligament scale) will need to be fully incorporated to understand the mechanical behavior of the foam. The integration of non-destructive measurement techniques with synthetic-data generation provides a path toward realistic modeling of bulk samples of open-cell metal foam resolved at the scale of individual grains.

For Research Use Only. Not for use in diagnostic procedures.