Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

The flow distribution behaviour of open-cell metallic foam fuel cell flow-fields are evaluated using ex-situ optical analysis and X-ray computed tomography (X-ray CT). Five different manifold designs are evaluated and flow distribution and pressure drop quantitatively evaluated with reference to applications in polymer exchange membrane fuel cells (PEMFC) and heat exchangers.

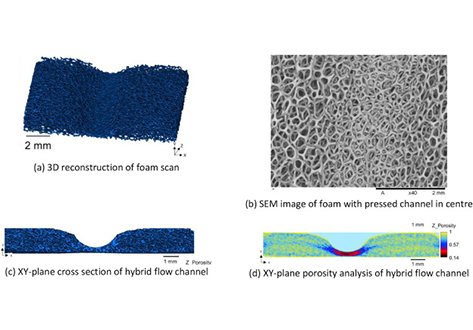

A ‘hybrid’ foam flow-field is presented consisting of flow channels pressed into the foam to promote flow distribution and reduce pressure drop. Cross- and through-channel pressure drop measurements are conducted, along with X-ray CT analysis.

Results using dyed water show that metallic foams provide excellent fluid distribution across the fuel cell flow-field, closely following the theoretical filling rate. The time for dye to cover 80% of the flow-field area was 61% faster with a foam flow-field then with no flow-field present. Pressure drop was seen to reduce with increasing foam inlet area to levels comparable to multi-serpentine flow-fields. The introduction of flow channels in the foam can further reduce pressure drop and provide more even filling of the foam, at the expense of increased residence time.

The single-phase material segmentation was reconstructed using Avizo software. The localised porosity in the z-direction (parallel-to-flow channel) was calculated from Equation (1) using ImageJ and Avizo software packages.

For Research Use Only. Not for use in diagnostic procedures.