Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

Wire arc additive manufacturing (WAAM) technology has attracted considerable interest in large-scale metallic components, but porosity and low deposition rate are the two dominating technical challenges in WAAM of aluminum alloy. In order to effectively solve these problems, a novel method of hot-wire arc additive manufacturing is used to fabricate aluminum alloy. Systematic studies are carried out to investigate the formation mechanism of the pores, the macro/microstructures, as well as the mechanical properties of the parts.

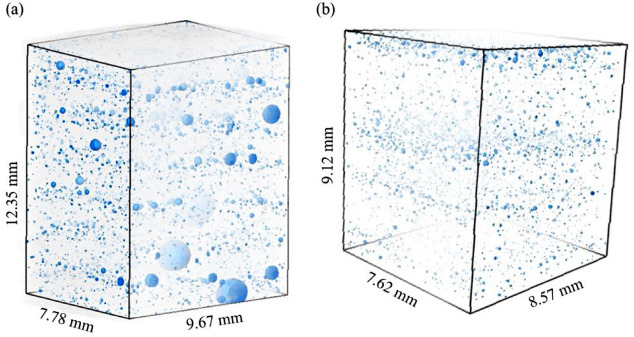

The microscopic pores were examined by X-ray computed tomography (XCT) […]. The number, the equivalent diameter and the spatial distribution of the pores obtained by XCT were counted by the Avizo 9 software.

For Research Use Only. Not for use in diagnostic procedures.