Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

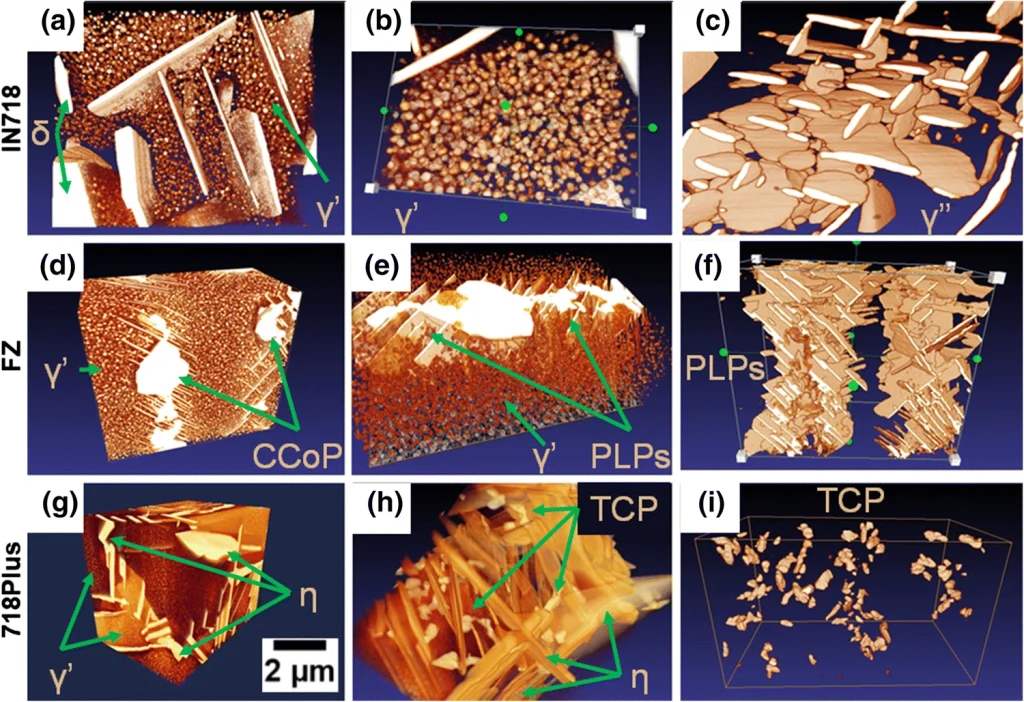

Inconel 718 (IN718) is the most popular precipitation-strengthened nickel-based superalloy introduced by the Huntington Alloys Division of INCO in 1959 (Ref 1). The IN718 is strengthened mainly by body-centered tetragonal γ″-Ni3(Al, Ti, Nb) phase and face-centered cubic γ′-Ni3(Al, Ti) phase. Its remarkable properties, including high strength, corrosion resistance, excellent creep resistance and good toughness up to about 650 °C, enabled the broad application of IN718 in aircraft and land-based gas turbine engines and components for liquid-fueled rockets. Microstructural changes of the Inconel 718 and ATI 718Plus® base materials and the fusion zone caused by the isothermal hold at 760 °C for up to 500 h were investigated. The evaluation was performed using a scanning electron microscope with backscattered electrons detector and scanning transmission electron microscopy supported by energy-dispersive x-ray spectroscopy. Furthermore, to evaluate the effect of microstructural changes on mechanical properties Vickers microhardness measurements were performed. Exposure of welded joint at high temperature led to coarsening and/or dissolution of main strengthening phases’ particles and nucleation and growth of plate-like precipitates. In the interdendritic region of the fusion zone, the transformation of the Laves phase to a complex cluster of precipitates contained σ phase had taken place. Analysis of microstructure and microhardness measurements showed that ATI 718Plus has better mechanical properties and microstructural stability at elevated temperature than Inconel 718.

The 3D reconstruction of the investigated areas of welded joint was generated using Avizo Software. Learn more about Avizo Software for metals and alloys

For Research Use Only. Not for use in diagnostic procedures.