Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

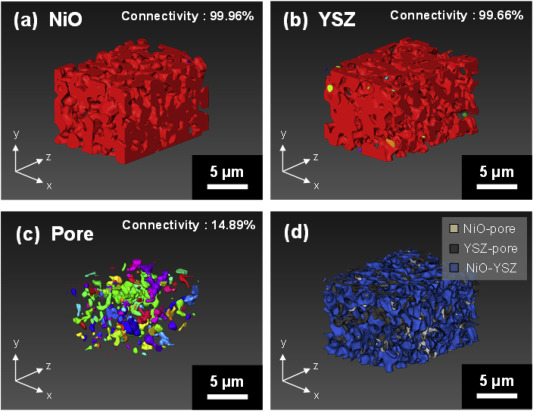

Nickel-yttria-stabilized zirconia (Ni-YSZ) cermet is widely used as an anode material in solid oxide fuel cells (SOFCs); however, Ni re-oxidation causes critical problems due to volume expansion, which causes high thermal stress. We fabricated a Ni-YSZ anode functional layer (AFL), which is an essential component in high-performance SOFCs, and re-oxidized it to investigate the related three-dimensional (3D) microstructural and thermo-mechanical effects. A 3D model of the re-oxidized AFL was generated using focused ion beam-scanning electron microscope (FIB-SEM) tomography. Re-oxidation of the Ni phase caused significant volumetric expansion, which was confirmed via image analysis and calculation of the volume fraction, connectivity, and two-phase boundary density. Finite element analysis (FEA) with simulated heating to 500–900 °C confirmed that the thermal stress in re-oxidized Ni-YSZ is concentrated at the boundaries between YSZ and re-oxidized NiO (nickel oxide). NiO is subjected to more stress than YSZ. Stress exceeding the fracture stress of 8 mol% YSZ appears primarily at 800 °C or higher. The stress is also more severe near the electrolyte-anode boundary than in the Ni-YSZ cermet and the YSZ regions. This may be responsible for the electrolyte membrane delamination and fracture that are observed during high-temperature operation.

For Research Use Only. Not for use in diagnostic procedures.