Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

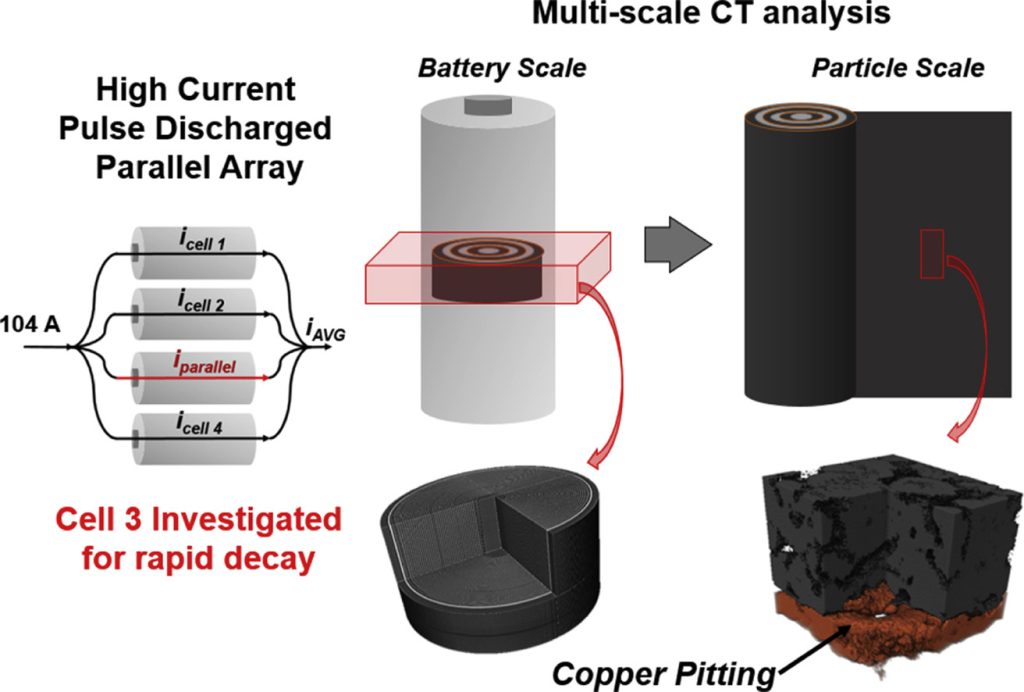

X-ray computed tomography (X-ray CT) across multiple length scales is utilized for the first time to investigate the physical abuse of high C-rate pulsed discharge on cells wired individually and in parallel.. Manufactured lithium iron phosphate cells boasting high rate capability were pulse power tested in both wiring conditions with high discharge currents of 10C for a high number of cycles (up to 1200) until end of life (<80% of initial discharge capacity retained). The parallel assembly reached end of life more rapidly for reasons unknown prior to CT investigations. The investigation revealed evidence of overdischarge in the most degraded cell from the parallel assembly, compared to more traditional failure in the individual cell. The parallel-wired cell exhibited dissolution of copper from the anode current collector and subsequent deposition throughout the separator near the cathode of the cell. This overdischarge-induced copper deposition, notably impossible to confirm with other state of health (SOH) monitoring methods, is diagnosed using CT by rendering the interior current collector without harm or alteration to the active materials. Correlation of CT observations to the electrochemical pulse data from the parallel-wired cells reveals the risk of parallel wiring during high C-rate pulse discharge.

For Research Use Only. Not for use in diagnostic procedures.