Thermo Fisher Scientific › Electron Microscopy › Electron Microscopes › 3D Visualization, Analysis and EM Software › Use Case Gallery

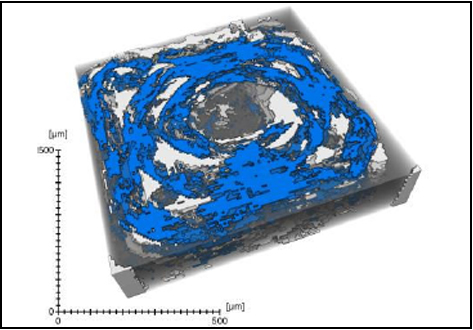

X-ray Computed Tomography (X-ray CT) has become a vital tool for product quality inspection. The X-ray CT analysis of 3D printed composites, with a layer-by-layer structure of carbon fibre/polyamide and polyamide plies, demonstrates how the void content increases with an increasing number of consecutive carbon fibre layers. Not only the void content, but also the pore network complexity increases, as more pore types are introduced into the sample. The PolyAmide (PA) matrix has an average void content of 6%, consisting of interbead channels with strong anisotropy. Alternating a carbon fibre layer with two polyamide layers slightly increases porosity (6.8% on average), as both inter- and intrabundle porosities are now present. It was found that the premature cutting of the carbon fibre bundle results in a large void at the end of the print path, while the start of the path is also associated with voids and an interruption of the PA wall layers. Full carbon fibre layering sections introduce additional large voids (average porosity of 9.7%), as the carbon fibre bundle cannot fully move into the corners of the polyamide wall layers.

The Phoenix datos|x software was used to reconstruct the X-ray CT scans and to export cross-sectional images. The data was further processed using the 2D/3D image analysis software Avizo (v9.5). Cross-section images and 3D volume renderings of the pore network were generated in Avizo.

For Research Use Only. Not for use in diagnostic procedures.