Featured articles using Thermo Scientific 3D image analysis software

Below you will find a collection of use cases of our 3D data visualization and analysis software. These use cases include scientific publications, articles, papers, posters, or presentations that show how Amira Software and Avizo Software are used to address various scientific and industrial research topics.

Select an industry and then applications or type in a search term to see cases related to specific topics you are interested in.

Search

Industry

Applications

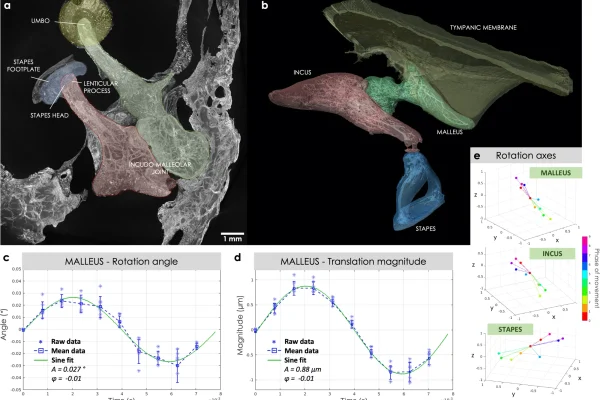

Margaux Schmeltz, Aleksandra Ivanovic, Christian M. Schlepütz, Wilhelm Wimmer, Aaron K. Remenschneider, Marco Caversaccio, Marco Stampanoni, Lukas Anschuetz & Anne…

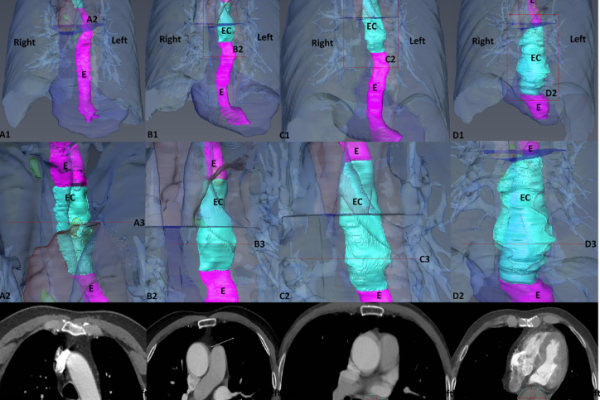

Runyuan Wang, Xiaoqin Zhang, Wei Wu, Jinfeng Ma, Jincheng Chen, Zhu Zhang, Liqun Liu, Shanshan Xu, Ximei Cao, Yi Wu,…

Xia Li, Feng Qiao, Jiansheng Guo, Ting Jiang, Huifang Lou, Huixia Li, Gangcai Xie, Hangjun Wu, Weizhen Wang, Ruoyu Pei,…

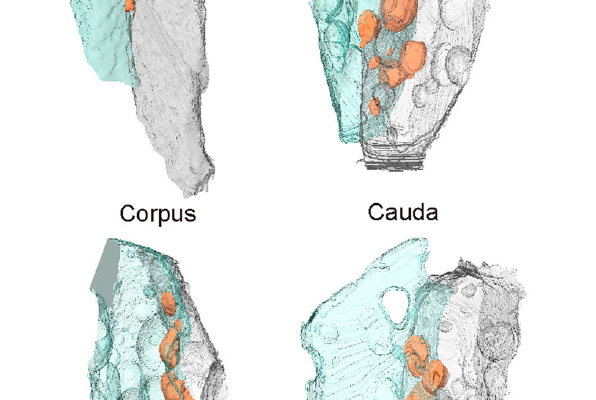

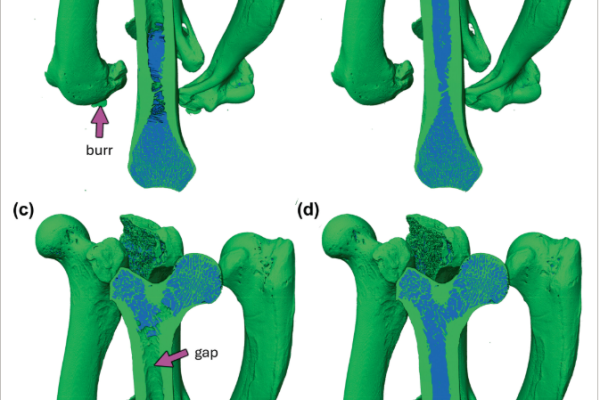

Eva C. Herbst, Alessandro A. Felder, Lucinda A. E. Evans, Sara Ajami, Behzad Javaheri and Andrew A. Pitsillides

Andrew H. Lee, Julian M. Moore, Brandon Vera Covarrubias, Leigha M. Lynch

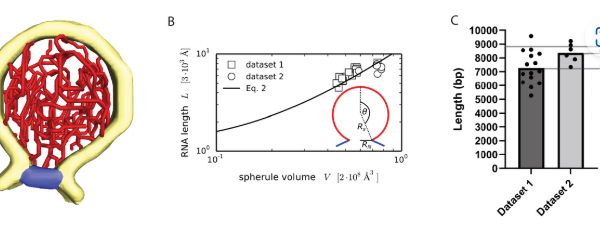

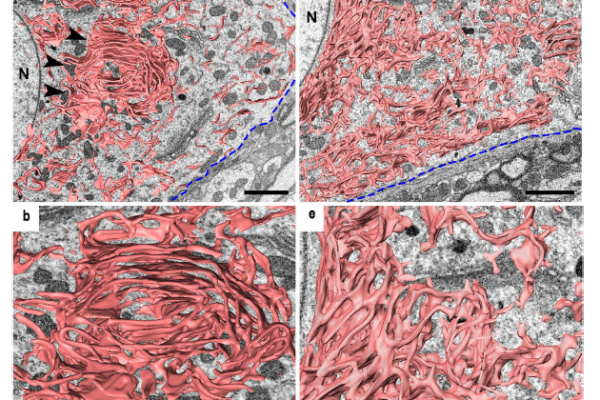

Timothée Laurent, Pravin Kumar, Susanne Liese, Farnaz Zare, Mattias Jonasson, Andreas Carlson, Lars-Anders Carlson.

B. Yu, T.A. Dijkstra, W. Fan, I.J. Smalley, Y.N. Wei, L.S. Deng

B. Yu, T.A. Dijkstra, W. Fan, I.J. Smalley, Y.N. Wei, L.S. Deng

Manguang Gan, Liwei Zhang, Yan Wang, Kaiyuan Mei, Xiaojuan Fu, Xiaowei Cheng, Mingxing Bai, Hejuan Liu, Xiaochun Li

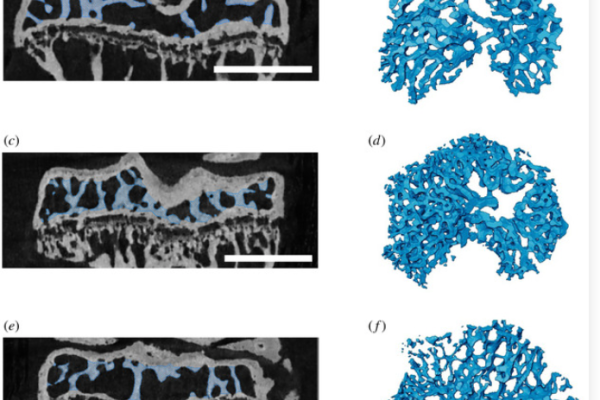

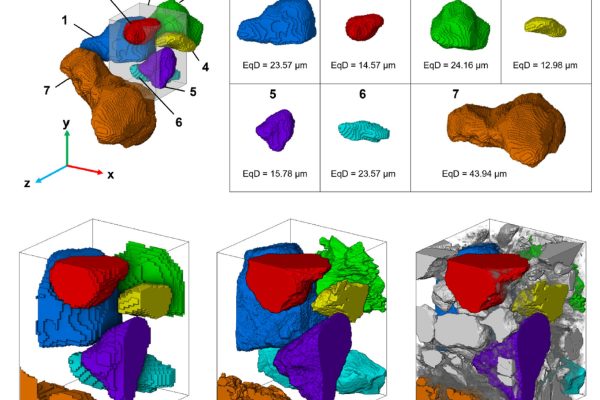

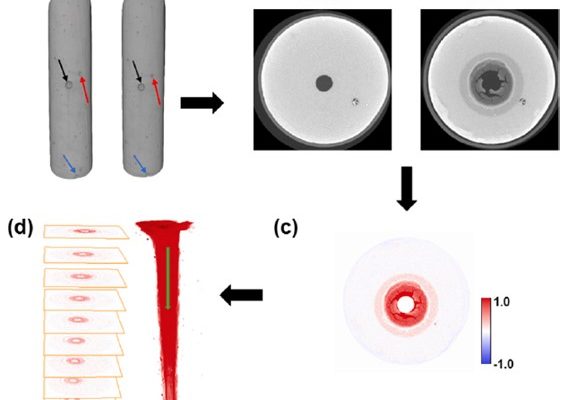

Matthew Sadd, Shizhao Xiong, Jacob R. Bowen, Federica Marone, Aleksandar Matic

Mahmoud Elgendy,Hiromi Tamada, Takaya Taira, Yuma Iio, Akinobu Kawamura, Ayusa Kunogi, Yuka Mizutani, Hiroshi Kiyama

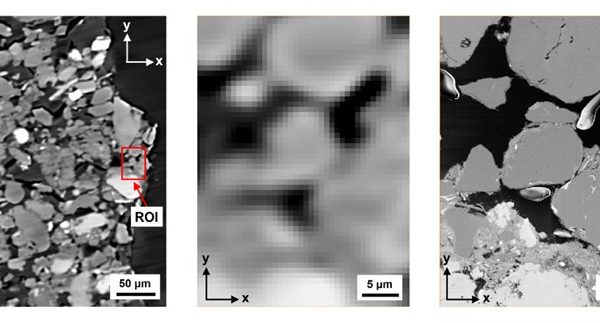

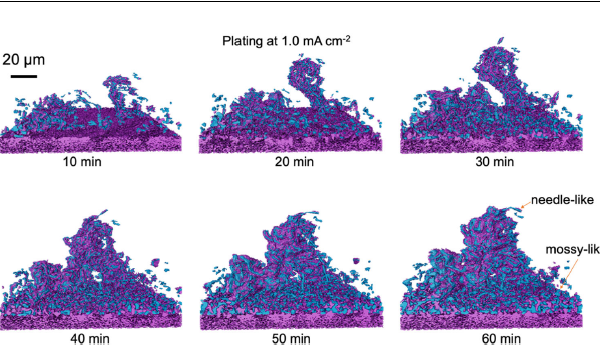

Zhennan Zhu, Shengqi Yang, Ren Wang, Jingyu Xie, Nuocheng Tian, Hong Tian, Jun Zheng, Guosheng Jiang, Bin Dou

For Research Use Only. Not for use in diagnostic procedures.